Add to Cart

It is not surprising that chemical etching aluminum parts in the aerospace, automotive, and electronics industries are growing. Aluminum has many desirable properties that make it a favorable option for components both in engine mechanical systems, electrical systems, and interior features and coverings. Although there are new types of composites emerging that are lighter and stronger, aluminum is less expensive because it is recyclable.

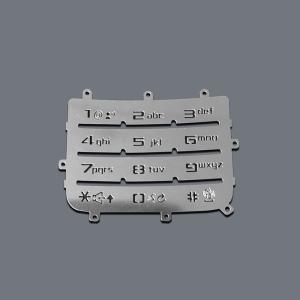

Photo etching is one of the most suitable manufacturing processes for thin aluminum components. Aluminum is a reflective material that is reactive to heat in the manufacturing process and therefore, makes it less suitable for laser cutting and wire EDM processes. Although challenging to manufacture, we have special equipment and processes that lower the temperature in the photo etching process so the metal properties remain unchanged while maintaining precision and low tolerances.

Metal fabrication with aluminum requires special processing to achieve the necessary burr-free surfaces and edges that are imperative in most components. Because aluminum is a reactive material and oxides easily, it can create a grainy build-up of material around the edges when exposed to light, a heated gas or an electrical current as used in laser cutting, plasma cutting, and wire EDM. Although these methods can cut aluminum, they are limited in capabilities with certain design features and dimensions especially if they are too close to an edge.

The more favorable fabrication processes for aluminum include stamping, punching, and photochemical machining. The ductility of aluminum allows for easy stamping and punching. However, those processes are not suitable for parts with complex or intricate designs and certainly not as economical for prototyping or shorter runs because the tooling is more expensive.

Here are the benefits of acid etching aluminum compared to other types of metal fabrication processes:

Many industries choose aluminum over other materials due to the attractive properties listed above. In particular, the aerospace industry requires durable, lightweight parts that will hold up in extreme temperatures or force.

Aluminum has a higher fatigue limit than other metals. Components in aircraft such as heat transfer plates have numerous lines that are etched simultaneously with the etching process. In large quantities, this type of part is more cost-effective to manufacture than other methods.

Likewise, the automotive industry can take advantage of the low-cost method when manufacturing aluminum components such as bipolar fuel cell plates. Just like heat transfer plates, the metal etching process is more cost-effective for these types of parts because they contain numerous channels. The process also saves time as both sides of the metal are etched simultaneously.

Any industry with electronic systems can count on the photo chemical etching for precision aluminum parts such as EMI/RFI shielding to resist the magnetic properties of neighboring components.