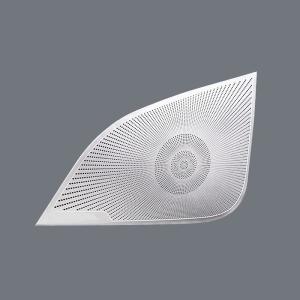

Precision Stainless Steel Etching Techniques for Industrial Applications

Decriptions of Stainless Steel Etching:

Our advanced stainless steel etching process delivers micron-level accuracy for industrial components, combining chemical etching and laser-guided technology. Ideal for aerospace, automotive, and machinery sectors, it ensures burr-free edges, corrosion resistance, and repeatable tolerances (±0.005mm). Compatible with grades 304, 316, and specialty alloys, we handle complex geometries, micro-perforations, and branding marks. Prototype to high-volume orders supported, with fast turnaround and ISO 9001-certified quality. Perfect for heat exchangers, sensor plates, and custom industrial identifiers.

Features of Stainless Steel Etching:

- High Precision & Detail: Achieves micron-level accuracy for intricate patterns, micro-text, and complex geometries.

- Material Versatility: Compatible with grades 304, 316, 430, and specialty alloys (e.g., duplex, martensitic).

- Burr-Free & Stress-Free Processing: Non-contact methods (chemical/laser) prevent mechanical deformation or edge imperfections.

- Design Flexibility: Supports custom logos, serial numbers, QR codes, and fine textures for functional or aesthetic purposes.

- Scalable Production: Efficient for prototyping and high-volume orders with consistent repeatability.

- Surface Finish Options: Matte, polished, or brushed finishes post-etching to meet industrial or decorative needs.

- Permanent Marking: Creates tamper-proof, wear-resistant identifiers for traceability (medical, aerospace, automotive).

- Cost-Effective Tooling: Eliminates expensive hard tooling; digital templates reduce setup time and costs.

Materials, Thickness and size we can stainless steel etching:

| STEEL AND STAINLESS STEELS | 0.01mm – 1.5mm | 600mm x 1500mm |

| NICKEL AND NICKEL ALLOYS | 0.01mm – 1.5mm | 600mm x 1500mm |

| COPPER AND COPPER ALLOYS | 0.01mm – 1.5mm | 600mm x 1500mm |

| ALUMINIUM | 0.01mm – 1.5mm | 600mm x 1500mm |

| TITANIUM AND TITANIUM ALLOYS | 0.01mm – 1.0mm | 600mm x 550mm |

Applications of Stainles Steel Etching:

-

High-end home audio systems and studio monitors.

-

Automotive speaker systems and marine audio setups.

-

Commercial venues (restaurants, theaters, retail spaces).

-

Architectural and custom-built speaker installations.

-

Outdoor entertainment systems and public address units.

Customization:

- Design Flexibility: Submit vector files (AI, CAD, DXF), sketches, or samples—we’ll replicate your vision flawlessly.

- Sizing Options: Available in thicknesses from 0.1mm to 1.5mm, with custom dimensions up to 600mm x 1500mm.

- Fast Turnaround: Rush services available (3-5 days) for urgent projects.

Why choose Xinhaisen?

- Accept personalized customization including logo, color, material, size, etc.

- Good quality, excellent after-sales services.

- 100% inspection before shipment and be responsible for all issues.

- 13 years of professional in Metal Chemical Etching.

- Experienced professional engineers team.

- High cost effective, short turnaround time and fast delivery.